Sunmax PVC hose factory have successfully upgraded the manufacturing process to significantly improve the adhesion between the reinforced ribs and the hose wall of pvc suction hose. This enhancement is particularly noticeable in corrugated-surface PVC suction hoses and has also been applied to smooth-surface types, ensuring superior structural integrity and durability across all product lines.

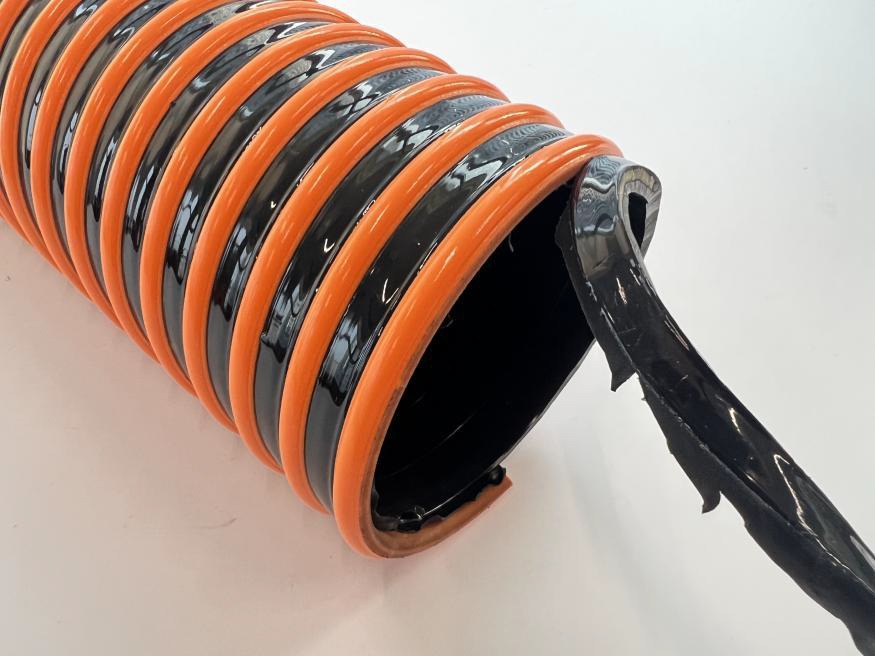

Before the upgrade, the bond between the reinforced ribs and the hose wall was not fully optimized. Under conditions of continuous bending or high-intensity operation, separation could occur, leading to potential hose failure—as illustrated in the below image.

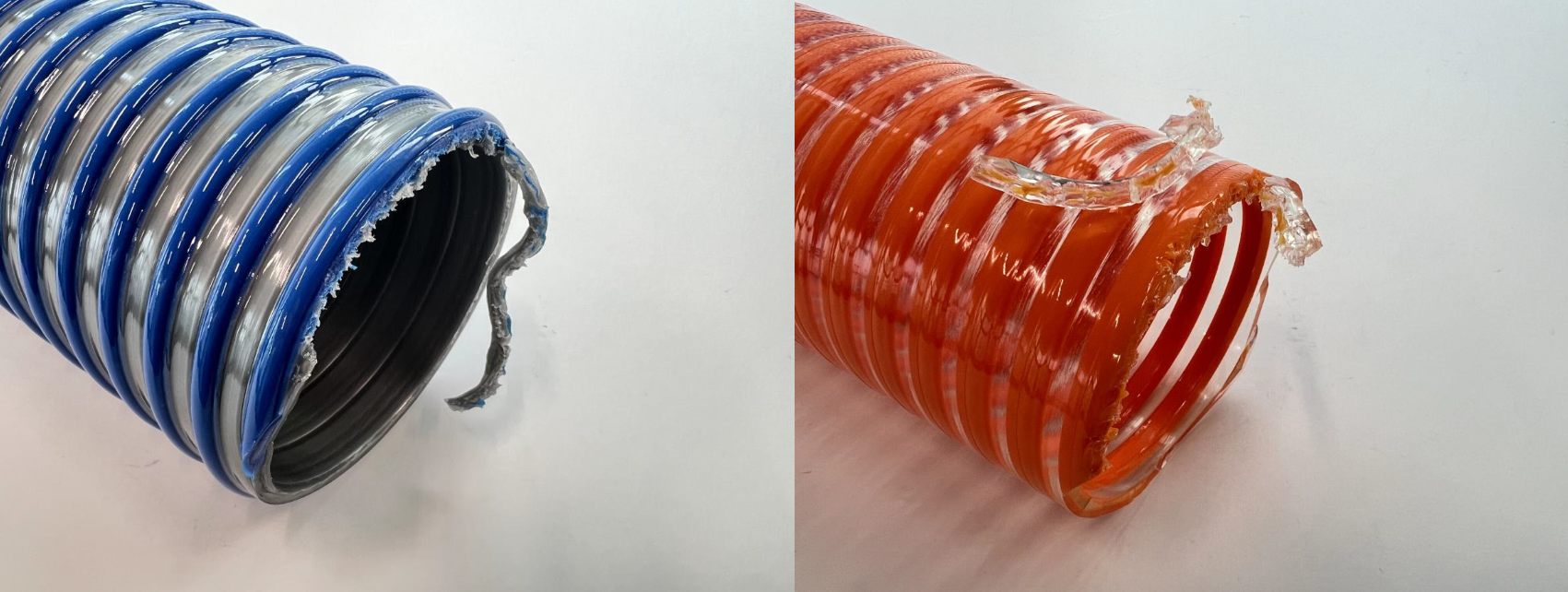

Our enhanced production method ensures that the reinforced ribs and PVC wall are now fully fused into a single cohesive structure. This complete integration prevents separation even under mechanical stress, substantially improving hose resilience in demanding applications.

Before Upgrade:

During the pull-off test, there is a distinct boundary between ribs and hose wall

After Upgrade :

During the pull-off test, Reinforced ribs and hose wall are completely fused. Even when forcibly peeled, the materials remain bonded—demonstrating exceptional resistance to tearing and structural failure.

Greater Durability: Withstands frequent bending and high-suction operations.

Enhanced Safety: Minimizes risk of sudden hose rupture.

Longer Service Life: Reduces maintenance and replacement frequency.

Consistent Quality: Applied across both smooth and corrugated hose types.

This process upgrade reflects our commitment to innovation and reliability. By achieving complete fusion between reinforcement and hose wall, we deliver stronger, safer, and longer-lasting PVC suction hoses—ready to perform in the toughest working environments.