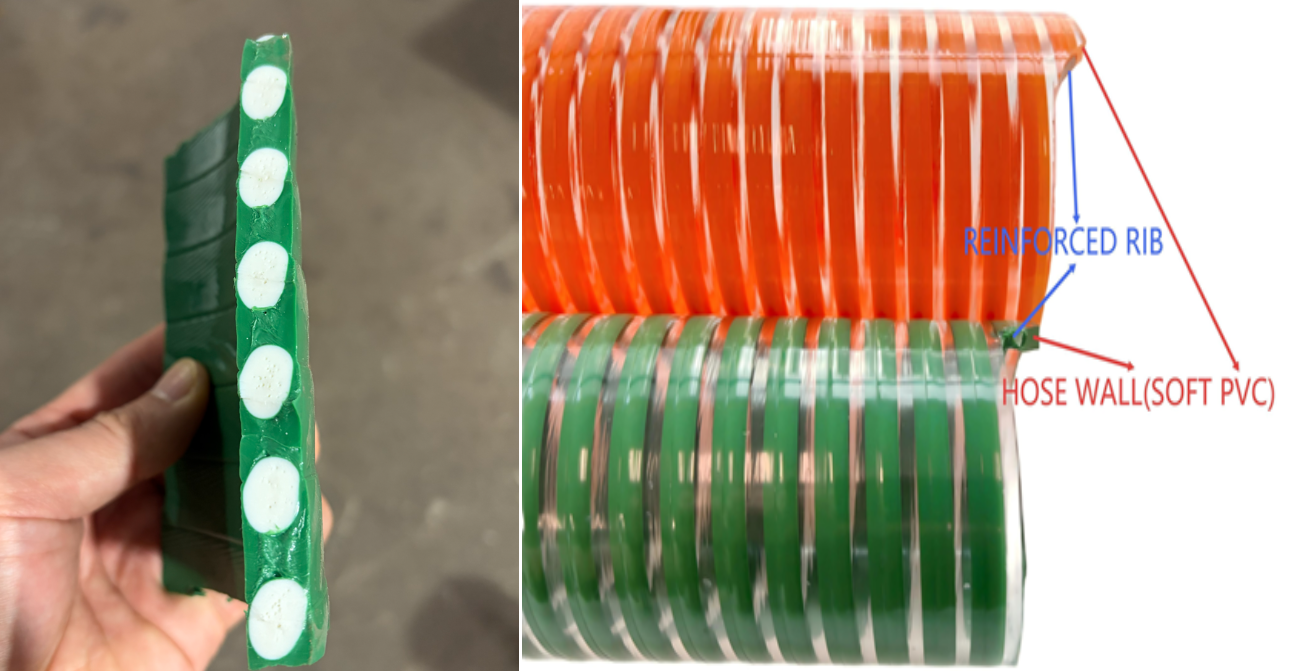

The reinforced rib is completely embedded within the hose wall, resulting in a smooth inner and outer surface.

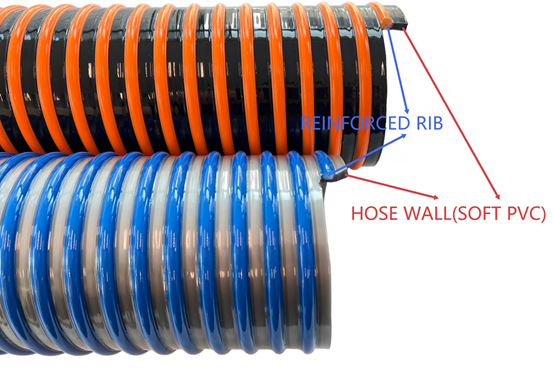

The reinforced rib is completely embedded within the hose wall, but the outer surface exhibits a distinct corrugated pattern.

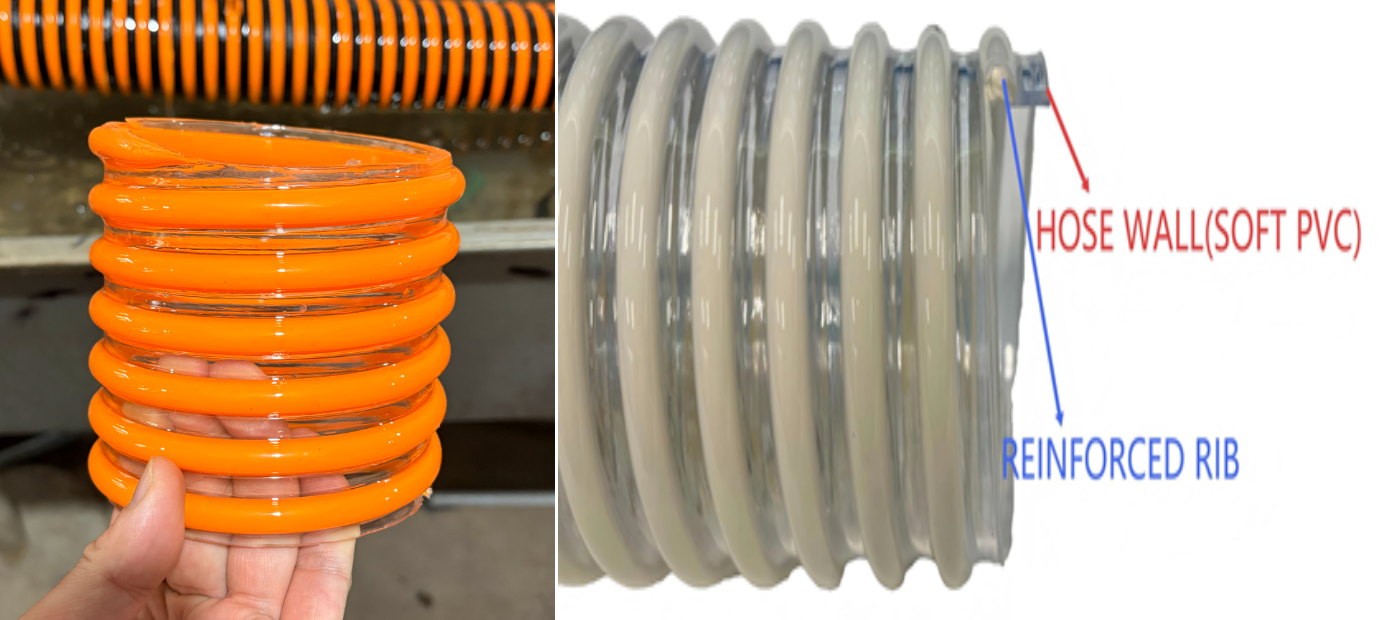

The reinforced rib protrudes from the outer surface of the hose wall, creating a corrugated surface.

| Feature | Smooth Surface PVC Suction Hose

| Corrugated Surface PVC Suction Hose

|

Wear & Pressure Resistance | -Thicker wall thickness makes the inner wall more wear-resistant -Allows the hose to withstand greater pressure when used for transportation purposes. | -Wall thickness is thinner,which makes the inner wall of the hose less wear-resistant. -Reinforced rib protrudes outside the hose wall, making the outer wall of the hose more wear-resistant. -Reinforced rib is thicker, which make the hose more resistant to suction. |

Flexibility & Friction | -Larger bending radius, less flexible. -High friction when dragged on flat ground, not ideal for dragging | -Smaller bending radius, more flexible. -Only the ribs contact the ground when dragged, resulting in low friction, suitable for dragging |

Installation Convenience | -High -Smooth surface allows for easy routing through narrow spaces or pipe sleeves | -Relatively Low -Protruding ribs may increase friction, making routing slightly more difficult |

Ideal for relatively fixed, low-friction suction and conveying applications.

Examples:

Fixed installed conveying lines in factories.

Industrial or agricultural water pumping.

Mining slurry/sediment suction.

Applications requiring a specific outer diameter (e.g., Spa Hose).

Ideal for applications where the hose is frequently dragged, moved, subjected to trampling/crushing, or experiences severe external abrasion.

Examples:

Tank truck suction hoses for sewage/waste.

Any application requiring continuous resistance to negative pressure (suction).